Pellet Mill / Disc Pelletizer

Pellet Mill / Disc Pelletizer

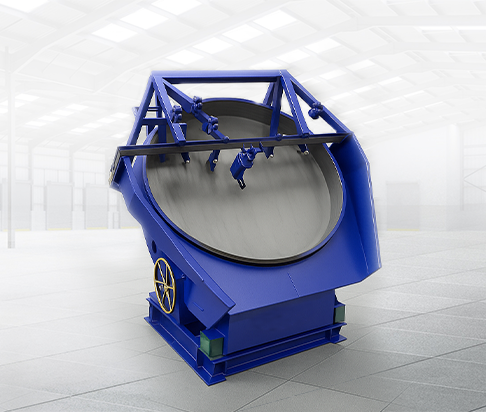

The VIRA Engineering Disc Pelletizer (Pellet Mill) is a highly efficient agglomeration machine designed for producing uniform pellets from powders, fines, and moist materials. The pelletizer consists of a rotating inclined pan mounted on a robust tilting frame. Feed material is introduced from the top, while liquid binders are sprayed through adjustable nozzles to facilitate pellet formation. The rolling motion within the disc ensures uniform granulation, with oversized pellets automatically discharged over the rim.

Pellet size and quality are controlled by pan inclination angle, rotational speed, binder amount, and feed rate. The system is ideal for industries requiring dust-free, uniform, and controlled pellet production.

Advantages

- Easy maintenance and simple operation

- Adjustable pan inclination for pellet size control

- Manual or motorized tilt mechanism

- Pan floor with self-cleaning rotating scrapers

- Variable speed control for uniform pellet quality

- Dust hood with exhaust connection for clean operation

- Special construction materials (MS, SS304, SS316, wear-resistant alloys)

Technical Parameters

| Pan Diameter | 1.2 m – 7.5 m |

|---|---|

| Pan Inclination | 35° – 55° (adjustable) |

| Capacity | 0.5 TPH – 30 TPH |

| Pellet Size | 2 mm – 20 mm (customizable) |

| Drive Motor Power | 2 HP – 75 HP |

| Material of Construction | Mild Steel / Stainless Steel |

| Binder System | Water, chemical solution, or steam spray |

Applications

-

Fertilizer industry

-

Cement & lime kiln dust recycling

-

Mineral & ore pelletizing

-

Fly ash, coal fines, & coke breeze agglomeration

-

Chemical powders, pigments, & catalysts

-

Environmental applications

Need Custom Equipment Solutions?

Our expert team can design and manufacture equipment tailored to your specific industrial requirements